Principles of medical cannabis production

The legalization of medical cannabis in many countries is driving the development of the growing industry. Production technology is improving due to research, and product quality standards are rising as the industry expands.

Growing medical cannabis

The manufacturers base their efforts on the principles of crop cultivation. Specialists in the field, along with scientists, conduct research and develop new techniques that have a positive effect on yields. They develop new strains of medical marijuana and improve the quality of the product.

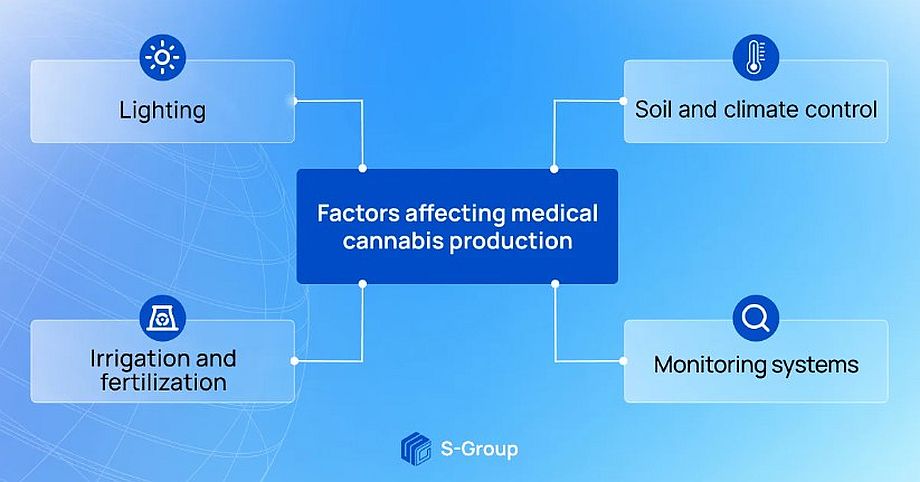

The success of the cultivation depends on many factors: soil, climate, lighting, irrigation and fertilization methods of the plants, and quality monitoring of the process. Let’s take a closer look at each of them.

Soil and climate control

Medical cannabis is hard to grow in an open space, and enclosed spaces are too expensive to use. Therefore, the optimal space for cannabis cultivation is a greenhouse.

The choice of materials and technologies for building greenhouses depends on the region in which it’s production is located. During cultivation, it is important to observe climate control, which can vary from strain to strain.

Lighting

Cannabis is very sensitive to sunlight, and its yield and quality are directly dependent on daylight control. Specialists have developed unique lighting systems for the medical cannabis industry. They have made the growing process independent of weather conditions and the length of daylight hours at different times of the year.

Irrigation and fertilization methods

The irrigation method for medical cannabis varies depending on the stage of cultivation. To automate the process, special irrigation systems have been developed for each of the stages.

The composition of cannabis fertilizer can also vary depending on the region’s climate, soil and plant species. Nutrients that increase the yield of medical cannabis are common and suitable for fertilizing many plant crops.

Monitoring systems

Special monitoring systems exist to control all medical cannabis cultivation processes. They allow producers to monitor product quality from the early stages of production and receive certification from state regulators.

Testing of cultivated products

Testing of grown medical cannabis is an important part of production. At this stage, the products are sent to special laboratories. There, scientists determine the quality of the finished cannabis based on the following indicators.

1) The ratio of CBD (cannabidiol) to THC (tetrahydrocannabinol) in grown cannabis. THC affects the human psyche, so its percentage in it should be minimal (up to 1%).

2) The strain of medical cannabis. The population of the same yield must be identical to each other. This is achieved by cloning the plants instead of growing them from seed.

3) Presence of pesticides and heavy metals. If the levels of toxic substances in the final product are higher than what is allowed, it will be recalled.

Labs for testing medical cannabis are gradually improving their testing methodology and equipment. Product testing increases consumer confidence in the industry. Quality certification helps them find legal distributors and buy a proven product.

Summary of successful medical cannabis production

The cannabis industry is expanding and improving the quality of products in official markets. Through the development of special technologies and methods, the cultivation process has improved and become more controlled. This has made it possible to monitor the quality of it and gain the trust of consumers.

S-Pharmaceutical is a Swiss company that produces and sells medical cannabis using advanced cultivation and product testing technologies.